Ceramic Anilox Shaft

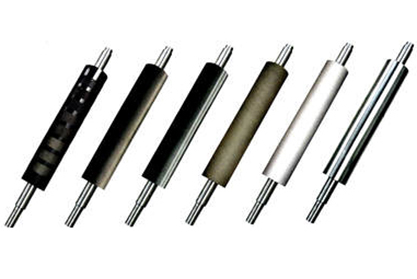

The anilox rollers we supply are manufactured using industrial plasma flame-spraying, laser engraving geometry and digital measurement technology giving our customer a precise and durable product at competitive price.

Ceramic Anilox Shafts

- Flexographic, lithography, gravure printing, UV coating

- Labels, envelopes, paper forms, handbags, corrugated boxes

- Coated & wood-patterned paper products, glazing, wallpapers

- Optical-, PE-, release-, and lithium battery diaphragm film, aluminium foil.

Each anilox roller undergoes eight highly precise manufacturing processes to meet all relevant roller standards and deliver high-quality anilox rollers for top-notch printing.

- Base Roller Processing: All bases are crafted from high-quality hollow seamless tubes.

- Sandblasting Treatment: This process ensures a secure surface key for the initial alloy adhesion.

- Nickel-Chromium Alloy Coating: The roller surface is coated with a nickel-chromium alloy that forms a strong bond with excellent metal affinity.

- Chromium Oxide Ceramic Layer: A plasma spraying system is utilized to create the working layer for anilox rollers, achieving an optimal hardness of approximately 1300-1450 HV.

- Carborundum Grinding: Silicone carbide stones are employed to grind the ceramic surface to precision.

- Carborundum Polishing: Micro-polishing with silicone carbide prepares the ceramic surface for engraving.

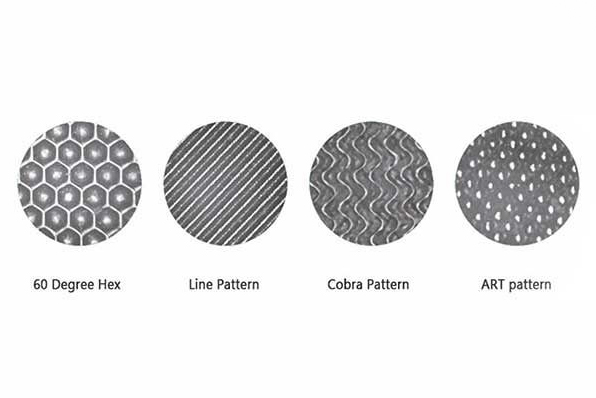

- Laser Engraving: This step involves direct application to the ceramic layer, allowing for precise cell size and etch depth for each cell.

- Polishing and Cleaning: This final stage ensures the removal of any “rough” edges and corrects cell wall irregularities.

We use the most advanced ALE optical laser engraving machines to ensure cell depth smoothness and consistency for even ink application and delivery across the entire roller face.

Screen Scope: 20-1800LPI

Diameter Range: 40-600mm

Maximum Width: 5000mm

Cell Shapes: See image below

When specifying an anilox roller, it’s crucial to define your specific requirements. To assist you in this process, we’ve compiled a set of guiding questions:

- What type of image will be printed? (Solid, line, halftone, etc.)

- What is the desired Anilox-to-Plate ratio?

- What is the substrate to be printed on? (Porous, treated, top-coated, etc.)

- What ink system will be employed? (UV, solvent-based, or water-based)

- How does the plate material behave?

- Are you using plate mounting tape, and if so, what type? (Cushion mount, etc.)

- What is your press speed and drying capacity?

If you find yourself uncertain about your roller specifications, you can rely on our Packadvance representatives to assist you in selecting the appropriate anilox roller to meet your unique printing requirements.

Business Hours

Monday - Friday: 8:00am - 17:00pm