Printing Rubber Rollers

Printing Rubber Rollers

These quality polyurethane rubber rollers consist of an outer rubber layer, a hard inner rubber layer, all mounted on a metal core, complete with a roll neck and a vent hole. These printing rollers are exceptionally well-suited for embossing and offset printing in high-speed printing lines.

- Flexographic, lithography, gravure printing, UV coating

- Offset

- Gravure

- Flexography

- Paper-, dry film-, hot- and cold lamination

- Nip rollers

- Foil processing

- Special UV compounds undergo rigorous chemical and physical testing before being applied to a #45 or #20 steel alloy base cylinder, following strict rolling, machining, and handling protocols.

- Balancing tests are conducted before shaft heads are installed, using hot charging techniques and welding.

- After the mandrels are attached, a dense outer rubber layer is coated and vulcanized to ensure optimal bonding quality.

- Grinding of the outermost layer is followed by meticulous polishing using CNC lathes, resulting in a seamless finish.

- Final testing is performed to confirm ideal concentricity, density, and tensile strength before packaging.

Type: Seamless Printing Rubber Cylinder

Base material: 45# Steel, 20# steel

Rubber material: NRB, UV, polyurethane, EPDM (Can be customised)

Hardness: Shore 5A-100D (Can be customised)

Operating temperature: -20°C to 120°C

Length: 50-8200mm

Diameter: 10-670mm

Colour: Varied

Tolerance: <0.05mm

Ink Compatibility: UV, Solvent Based, Water Based and Oil Based Inks

-

Easy Installation: Our rollers come equipped with pre-mounted bearings and gears, simplifying the installation process.

-

High Quality: Manufactured in compliance with ISO standards, our rollers possess core weight, hardness, and wall thickness that ensure high output, guaranteed concentricity, and excellent bonding to metals.

-

Durable: The incorporation of special UV compounds makes our rollers resistant to chemical corrosion and excessive wear. Additionally, they enable cooler print runs without scumming.

-

Dimensional Stability: Our rollers exhibit minimal resetting requirements, even when subject to shrinking or swelling.

-

Ink Transfer: Our compound resists ink permeation, reducing glazing and dot gain, resulting in optimal ink transfer.

-

Versatile: Printing can seamlessly alternate between UV and oil-based inks.

-

Economic: Our rollers reduce downtime associated with resetting and outlast traditional rollers, ultimately leading to cost savings.

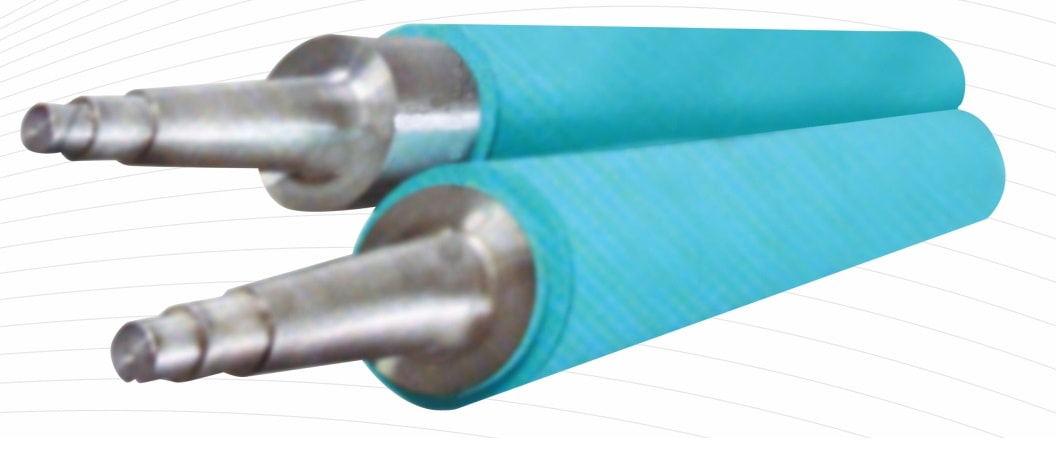

Examples of rubber rollers

Rubber Impression Rollers

Our rubber rollers boast outstanding characteristics, including high resilience, exceptional wear resistance, resistance to ageing, and remarkable geometric accuracy.

Key Specifications:

- Straightness and Circular Run-out: Within a scope of ⩽ 0.02 mm.

- Superior Hysteresis Quality: Featuring a stable press zone and an error value scope of ⩽ 2 mm.

Rubber Ink-drop Rollers

Our rubber rollers are built to withstand the harshest environments, offering acid-proof, alkali-proof, and organic solvent-resistant properties. With a swelling set scope of ⩽ 2%, these rollers effectively eliminate ink bubbles and ensure consistent and even ink transfer.

Static Ink Absorbing Rollers

Our rubber rollers are meticulously designed to offer both balance and stability in surface resistance measurement. They provide reasonable and safe insulation resistance, combined with exceptional wear resistance and high proof pressure capabilities.

Furthermore, these rollers undergo low-frequency grinding, ensuring a prolonged usage lifespan while maintaining optimal performance.

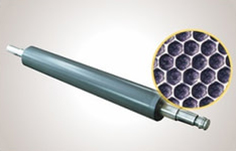

Solvent Free Transferring Roller

Our rubber rollers are engineered to deliver unparalleled geometric precision. With a straightness and run-out scope of ⩽ 0.02 mm, these rollers ensure meticulous alignment and operation. Additionally, the press zone error between the Rubber Roller and Steel Roller is kept within ⩽ 2mm.

Moreover, these rollers exhibit exceptional geometric precision and maintain a glue coating value error of ⩽ 10%, guaranteeing consistent and reliable performance.

Examples of industrial rollers

Industrial rubber rollers, along with rollers made from various materials, find application in a wide array of industries, including papermaking, leather production, metallurgy, printing, dyeing textiles, and furniture manufacturing.

To cater to the specific technical demands of various products, we have developed technologies that not only ensure customer satisfaction but also uphold industry standards.

Curved Roller

Spinning Roller

Laser Roller

Polyurethane Roller

Wool Roller

Leather Wallpaper Embossing Roller

Sponge Roller

Oil Paint Roller

Sanding Smooth Roller

Chroming Roller

Mirror Finish Grinding Roller

Ceramic Roller

Business Hours

Monday - Friday: 8:00am - 17:00pm